Note: this page is in development and is not a finished product. Following content should be regarded as preliminary.

Operational guidelines - Sea operations

Challenges with LSFOs at sea, and possible solutions.

Challenges with LSFOs at sea, and possible solutions.

Note: this page is in development and is not a finished product. Following content should be regarded as preliminary.

LSFO slicks at the sea surface may behave differently than conventional oils depending on the LSFO’s physical-chemical properties and temperature.

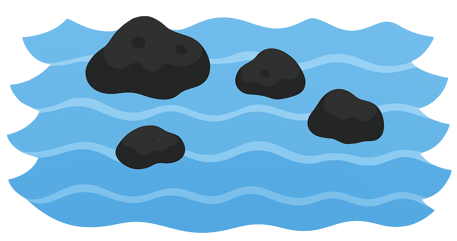

LSFOs may appear as either fluid, semi-solid or solid slicks at the water surface. This is highly related to the variability in pour point of LSFOs. Some LSFOs may not form a slick at all but appear as small solid lumps in the water.

Some LSFOs can be submerged in the water column, and reappear to the water surface, creating challenges with detection and containment.

Use of chemical dispersants have shown little effect on several LSFOs, much due to high viscosity and/or waxes content. No safety issue related to flammability is raised with LSFOs (with flash point above 80°C for all the oils tested). In-situ-burning have shown low efficiency.

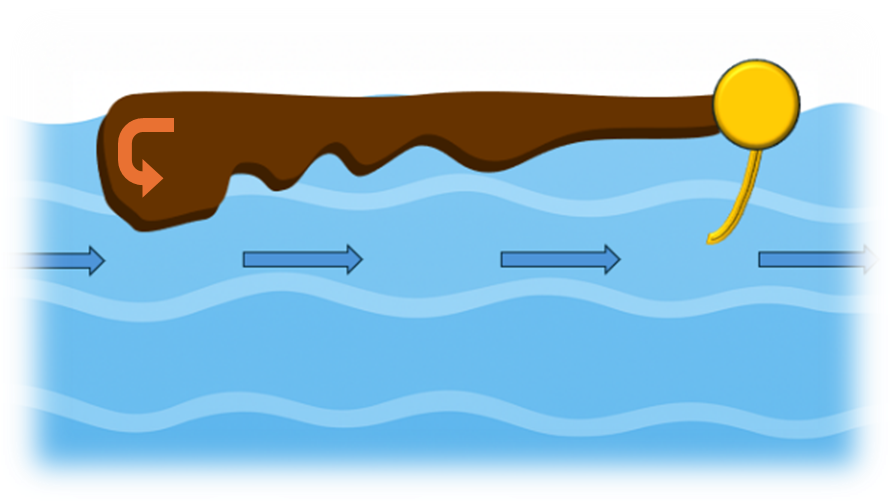

Solid or semi-solid oil slicks can have varying thickness throughout the slick, where the thickness is often highest at the far edge of the slick, furthest away from the boom. These slicks may also roll at the edge and accumulate at the far edge from the forces of the water current, which does not allow for large concentration of oil near the apex of the boom.

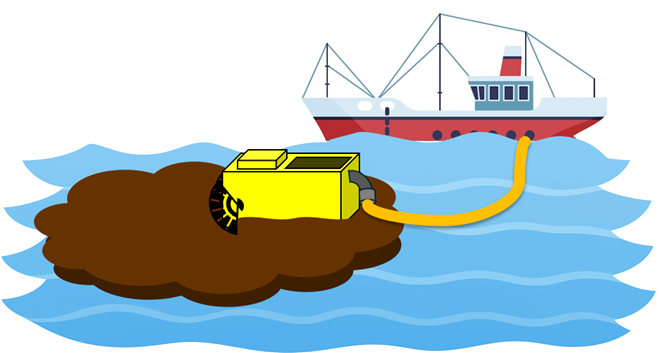

LSFOs may exhibit poor inflow and low adhesion to oleophilic skimmer surfaces and recovery equipment.

Some LSFO’s behaviour at sea causes poor inflow to the skimmers, due to properties such as solid or semi-solid oil slicks or lumps, low adhesion to oleophilic surfaces, or the oil having “short” properties where the oil would not continuously float towards the skimmer during recovery.

Oil bridging in front of skimmers or other obstacles can occur, preventing oil flow into the skimmer.

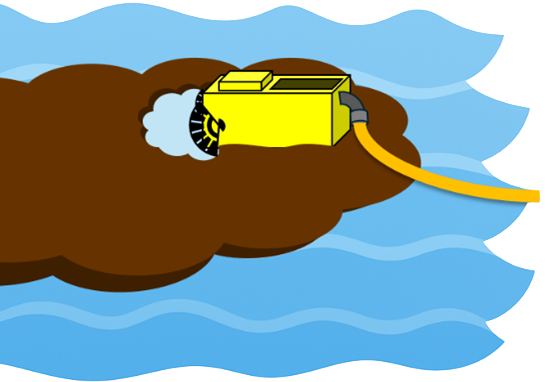

Solid/semi-solid LSFOs may stick to the sloped sides of the hopper’s walls, thus preventing it from reaching the pump.

Recovery equipment must be flexible/adaptable to LSFO’s variability in behaviour at sea. The right choice of recovery equipment depends on the specific physical-chemical properties and behaviour of the oil, temperature and the location of the spill.

Much success has been shown when using skimmers with thrusters or other mechanisms to manoeuvre the skimmer actively into and inside the oil slick to recover LSFOs with poor flow properties, such as semi-solid and short oils.

Since the oil thickness of some LSFOs can vary greatly within the slick, and have highest thickness furthest away from the boom, the optimal point of attack for efficient recovery is not always in the apex of the boom but operating the skimmer from the “seaside” furthest away from the boom, when encountering oil slicks with varying thickness.

Using skimmers with multiple configurations, such as adjustable immersion depth, operating speed and interchangeable brushes, discs, belts, etc. can help the skimmer to adapt for the specific behaviours of LSFOs.

When encountering poor oil flow inside the hopper, applying energy to the oil in the hopper such as heating, mechanical movement or water injection etc., or having the hopper and pump closer together can help the oil flow to the pump.

If an LSFO with solid or poor flow properties is collected in a storage tank, it can be challenging to get the oil out of the tank without applying energy such as heating or an internal pump.

Solid oil lumps can be recovered with excavator bucket or nets directly to a collection tank.